Yizumi made an appearance with its automatic die casting system in the 2nd Smart Expo on October 31 in Shunde. The exhibtion had three areas: intelligent manufacturing area, Internet of Things area and smart city area, presenting the industry-leading products and cutting-edge technology and application. The exhibition was expected to combine industry, academy, development and purchase, display successful cases and solutions, focus on new technology and policy trend, and provide the demand and supply information platform.

Shunde is the epitome of China's industrial development. With the need of industrial transformation and upgrade, Shunde, a typical manufacturing city in the Pearl River Delta, has made pioneering exploration in intelligent equipment, intelligent products and intelligent services.

In 2011, Shunde became the pilot city for intelligent manufacturing and thorough integration of information and industrialization. With two years of development, Shunde establishes a primary smart manufacturing system featuring intelligent machinery, industrial robots and intelligent household appliances. It is reported that since 2011, Shunde has selected 69 intelligent manufacturing model enterprises including Yizumi and the city hosts the densest intelligent manufacturing enterprises clusters in Guangdong Province.

Yizumi was one of the first model enterprises that started exploring intelligent manufacturing in production management early: carrying out computer-aided product design, three-dimensional design and simulation design, conducting the electronic data display board project, providing information on each machine throughout the assembly according to the progress of machine assembly, commissioning, testing and other production processes, developing remote diagnosis system, offering online after-sales services including diagnosis, maintenance and upgrade, developing real-time monitoring system and achieving network information management.

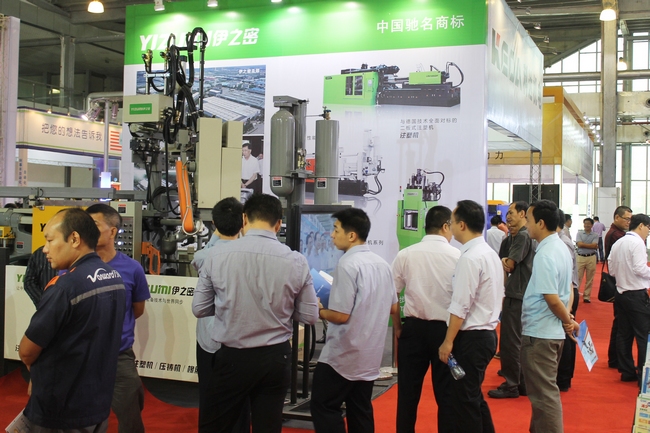

At this expo, Yizumi displayed an automatic integrated die casting system. Under the intelligent control of an embedded controller, the die casting machine and peripheral equipment can automatically make the raw materials into qualified castings. The unmanned die casting process reflects sequencing, digitization and remote control. The production management information system has functions such as online product testing and automated logistics. Key intelligent measure and control parts include intelligent detection system for air content in melt, embedded dedicated controller, automatic three-dimensional servo spraying machine, automatic quantitative pouring system, high-temperature and corrosion resistant assembly and pickup robot and online intelligent detection system. Currently die casting manufacturing in China almost requires both manual work and mechanical automation, causing problems such as high scrap rate and poor quality consistency. The application and promotion of automatic die casting production system plays an important role in enhancing technological level of China’s die-casting industry , narrowing the gap with world-leading technology, taking on developed countries’ long-term monopoly of the technology and accelerating upgrade of China’s die casting industry.

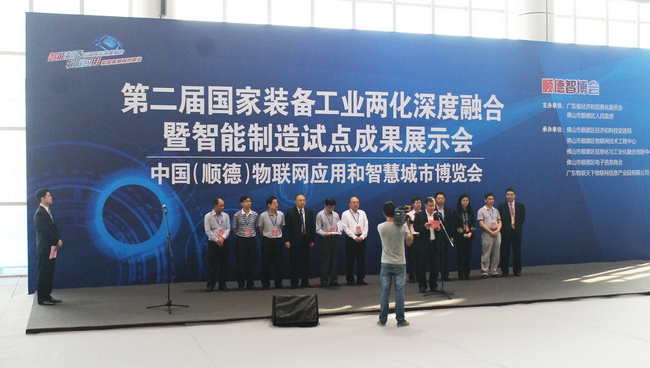

At yesterday’s opening ceremony, the Economic & Information Commission of Guangdong Province and Shunde Government signed “Framework Agreement on Jointly Promoting Construction of Intelligent Manufacturing Industry Bases in Guangdong”. In addition, the opening ceremony included the unveiling of two plaques—“Guangdong Intelligent Manufacturing Base” and “Guangdong Intelligent Industry Alliance”. The Alliance is to promote the cooperation of intelligent manufacturing and enterprises throughout Guangdong Province for coordinated development, jointly develop domestic and overseas markets for intelligent manufacturing, improve the technology and competitiveness of intelligent manufacturing in Guangdong and boost the industry application and regional intelligent manufacturing development.

Yizumi displays automatic integrated die casting system

The opening ceremony

The opening ceremony

Signing the agreement

Plaque unveiling ceremony