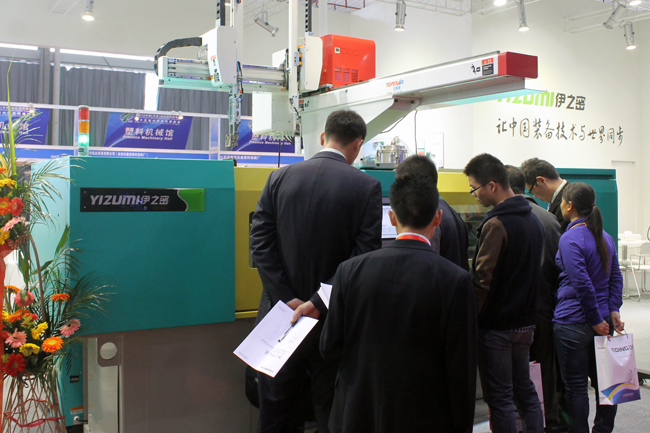

Crowned as “The No. 1 Expo in Chinese Plastic Industry”, the 15th China Plastics Expo was held in Yuyao, Zhejiang from November 6 to 9. The annual event which is a platform for market development and information exchange gathers a group of domestic and overseas companies related to plastic raw materials, molds, machine tools and plastic machinery. As a regular exhibitor of China Plastics Expo, Yizumi targeted electronic communications and packaging industries that flourish in Yuyao and the surrounding areas, and showed two innovative turnkey solutions: a 60-ton all electric injection molding machine (model FE60S) and a 120-ton injection molding machine for cell phone parts (model UN 120SJ). They are the latest results of Yizumi’s technical research and development.

FE60S is the first Yizumi-developed all electric injection molding machine that combines advanced technologies of Japanese and European machines and is especially suitable for precision injection molding of packaging, medical and digital products. FE series represents world-leading drive technology, user-friendly design, and digital processing technology, and also features energy saving, high speed, high efficiency, precise control, reliable running and simple operation. This new machine will provide advantages for customers who have the need of professional injection molding. At the booth, the machine produced plastic gears with 4-cavity mold and cycle time of only 15 seconds, showing strong competence in large-batch production and precision molding.

UN120SJ injection molding machine for cell phone parts was launched in 2013 and specially designed for high-end intelligent mobile phones, with an aim to strengthen Yizumi’s competitiveness in sub markets such as electronic, electrical, small household appliances and LED industries. This new machine works in high speed smoothly with injection pressure up to 300 Mpa that guarantees production of products with higher ratio of flow path to wall thickness. This machine is 40% faster than the general-purpose injection molding machine and lowers the internal stress of products during high-speed filling to reduce the possibility of deformation. Deviation of temperature control in static test is plus or minus 1℃ and deviation of platen parallelism is within 50% of national standards, with less wear of the mold. This machine is stable in molding with higher level in automation and deviation of mold opening and clamping precision within ±0.5mm. With 20% less dry cycle time, the machine offers higher productivity as well.

Statistics show that the four-day exhibition attracted about 500 exhibitors and over 20 thousand buyers, up by 2% year on year. With the excellent performance of two machines and decent decoration of the booth, Yizumi managed to draw the attention of plenty of visitors and acquire a number of purchase orders. Yizumi’s performance in the 15th China Plastics Expo further promoted its brand image and technical strength in east China.