Shunde Bureau of Economic, Scientific and Technological Promotion conducted an appraisal of the project “R&D of high-speed and high-efficiency PET preform injection molding system” that was taken on by South China University of Technology and Yizumi on December 13. The appraisal panel which was led by Guangzhou Institute of Mechanical Design Institute Prof. Chen Jinfeng evaluated the result of project R&D, inspected the manufacturing site of sample machine, heard the conclusive report on project implementation, reviewed relevant documentation submitted for appraisal and inquired about the project implementation. In the end, the appraisal committee reached a consensus that the technology and product referred to in the project ranked top among their counterparts nationwide and approved that the project passed the scientific and technological achievement appraisal.

The injection molding system, as it is referred to in the project name—R&D of high-speed and high-efficiency PET preform injection molding system—is equipment based on technologies of servo drive, differential pressure-controlled high-sensitivity mold protection and new linear motor-driven robot for preform extraction. This energy-saving and environmentally-friendly injection molding system can produce high-quality PET preforms with near net shape. Tested by Guangdong Province Machinery Inspection Agency, the newly developed injection molding system conforms to JB/T 7267-2004 Requirements for Injection Moulding Machines and it is widely recognized by users. In addition, the jointly developed project has gained a patent for invention and four utility-model patents and Yizumi has corresponding independent intellectual property rights.

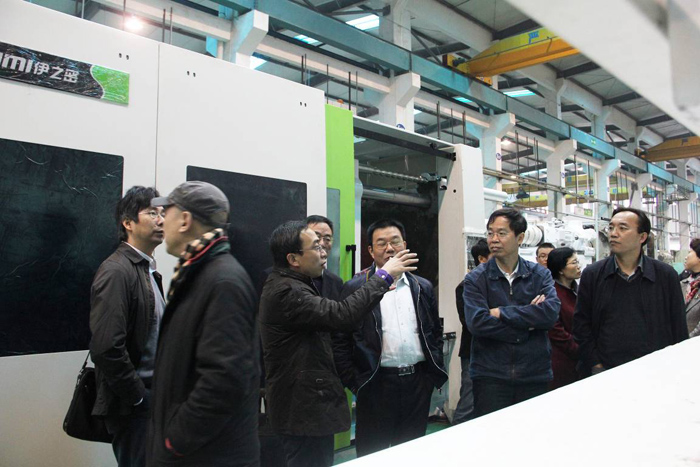

The appraisal panel inspects the machine manufacturing site

Yizumi high-speed and high-efficiency PET preform injection molding system