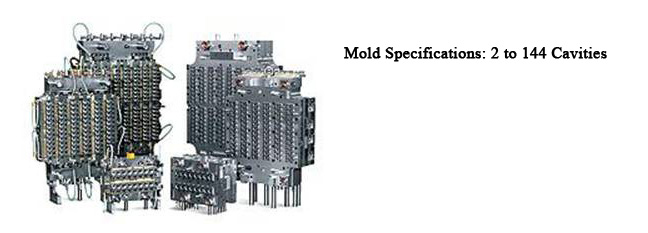

PET Preform Molds

-

Cold Half

- Die lip with patented water channel design to achieve more even cooling and to ensure dimensional stability of preforms.

- Cavity cooling channel design based on CFD analysis, improving the preform cooling and shortening the production cycle.

- The cold half core of PET preform molds is made of imported 420ESR tool steel and subject to special surface treatment to ensure the tool life up to 8 million cycles.

- The core rod and die lip employs Vapor Honing special surface treatment for easy ejection and reduced ejector resistance.

- The core with heat treatment is subject to special anti-corrosion treatment so that the cooling channels are durable with good resistance to rust.

- The mold core plate, cavity plate and other mold bases of cold half are made of with 2316 high-strength stainless steel to ensure long service life.

- The core taper of PET preform molds is processed via a precision Swiss grinding machine to ensure accuracy of 5 microns and to avoid premature wear of die lip.

- Hot runner manifold design using natural balance to ensure 90-degree turns.

- The runner diameter is based on mold flow analysis and appropriate pressure drop design, ensuring the minimum cavity pressure during injection and prolonging the service life of the core

Major components of the valve gate, such as nozzle, insulation cap and valve pin are manufactured by Canadian professional subcontractor. The valve pin of PET preform molds matches the pin sleeve diameter, with dimensional tolerance of 3 microns as required, significantly reducing the risk of plastic leakage.

The bolts of hot half plate are carefully arranged as technically required and tightened according to bolt torque specifications. Thermal expansion of PET perform molds will never cause deformation of the hot half plate or plastic leakage.

The hot runner structure, with the latest disc spring design, has high capacity of thermal expansion absorption. The patented design of valve gate components and cylinder structure offers ease of maintenance and prolongs the life of seals. The design of hot runner is based on finite element analysis and thermal conduction analysis, which delivers high reliability and ensures no plastic leakage. The hot runner system of PET preform molds does not need complete maintenance until it is used for over 5 years.