FE Series All-electric Injection Molding Machine Products > Injection Molding Machine

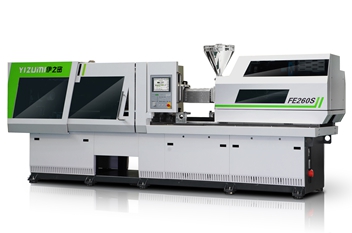

FE Series All-electric Injection Molding Machine

Clamping force ranges from 60 to 260 tons

As a combination of internationally dominant all-electric injection molding machine technology and actual situation of market application, FE series is widely used in electronics, appliances, photoelectric and digital products, automotive, aerospace, medical devices, food and cosmetic packaging, sporting and recreational goods and other markets.

Characteristics:

- Redoubled robust frame design versus common hydraulic machines and overall heat treatment that ensures sturdiness, durability and high resistance to deformation in long-term operation.

- New clamping mechanism: the new structure of clamping unit helps increase mold opening force by over 20%, lengthen the toggle stroke by nearly 15%, remarkably improve the work efficiency of machine and optimize the motion characteristics.

- Top plasticizing unit: screws are subject to surface treatment, like nickel-tungsten alloy brush plating, which makes the screws more resistant to corrosion and acid and eliminates defects in plasticizing, such as browning, black spot, uneven mixing and under-purging.

- High Efficiency and Repeatability:

- The shortest cycle time in fully-automatic production is within 3 seconds.

- The machine is capable of multiple synchronized movements and fast response.

- Dedicated ultra-fast ball screws, with the advantages of accurate positioning, low noise and long life, are adopted to handle high load.

- Energy-saving and Environment-friendly:

- Intelligent lubrication with high-performance grease avoids pollution and waste.

- Low-noise design.

- Reliability and Safety

- High-rigidity platens and highly-sensitive smart mold protection system.

- High-accuracy absolute encoder ensures stable torque, speed and position of movements and makes sure the reference point of linear axis will be kept during an outage.

- Advanced European Controller

- User-friendly: visual free programming via graphical icons and one-button data importing.

- Safety: interlock of the control and mechanical systems and multi-level user access.

- Convenient system maintenance and upgrade: versatile flexible I/O extension modules for adding extra functions as needed, in favor of troubleshooting. Wireless or wired remote transmission is available and facilitates more effective control.

- Quality control: production process data control, SPC, process capability index analysis and multi-waveform monitoring.