|

HPM North America Corporation |

Unfortunately, the financial crisis in 2008 hit the 131-year-old HPM hard and forced the company to shut down. In March 2011, Lanteky® Machine, successfully purchased all HPM intellectual property including technical drawings, customer resources, trademark, patents, and so on. In July, 2011 HPM NA was founded in Marion, Ohio, which was close to where HPM was formerly located. HPM NA was able to resume its SPI membership, and joined NADCA (North American Die Casting Association) in August. At present the plant area is around 2100m2 (22500 ft2).

To continue former HPM’s success and to better serve all HPM customers around the world, HPM NA hired the key executives and senior technical specialists of former HPM to join the company, including:

Mr. William Flickinger, former HPM president, who has worked 33 years at former HPM, and started as a mechanical engineer. Mr. Flickinger holds master’s degrees in mechanical engineering and quality management. During his career at HPM, the company grew to over one hundred million US dollars sales per year.

Mr. Brain DeBoer,senior electrical control engineer, who has worked 10 years at former HPM and 5 years at Visi-Trak, and studied and helped develop the shot control for die casting machines. Mr. DeBoer is an expert at Siemens and AB control systems, and holds a bachelor degree in electrical and electronic engineering.

Mr. Daniel Kane, a veteran from Vietnam war, who has worked 25 years at former HPM as a service manager, and developed a quick response service system to meet the needs of customers in time.

Mr. Howard Radel, service and parts engineer, who has worked 28 years as a mechanical engineer for extrusion equipment, and holds a bachelor degree in mechanical engineering.

Mr. Don Jagger, has worked 20 years at former HPM as a service engineer in charge of testing new machines and in their R&D lab.

Mr. Carl Hess is a graduate engineer and worked at HPM in the R&D lab and as a service engineer for both die casting machine and injection molding.

Mr. Randy Clements, General Manager for Bivouac worked at HPM in controls engineering.

Engineers from HPM NA are studying the designs of HPM machines with their Lanteky counterparts. The two sides will develop new machines with high performance and reliability for customers through cross-border technical cooperation, at a competitive price.

In November, 2011, HPM NA received its First order for two HPM 2000 ton die casting machines from a loyal Canadian customer.

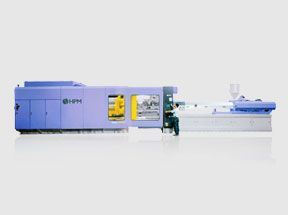

In February, 2012, HPM NA showed an injection molding machine at NPE2012 in Orlando in April.

Some of our current customers are General Electric, Orlick, AMT, Suncast, CK Technology, Windsor Mold, and Albany Chicago.

Our mission is to use the HPM technology developed over 135 years combined with modern control technology to R&D and manufacture the best performance-price machines to satisfy our customer needs.

Our vision is to become the first choice and the best choice for our customers in the world.